PowerLift® Saved One Company Nearly $1,000,000

Here’s How

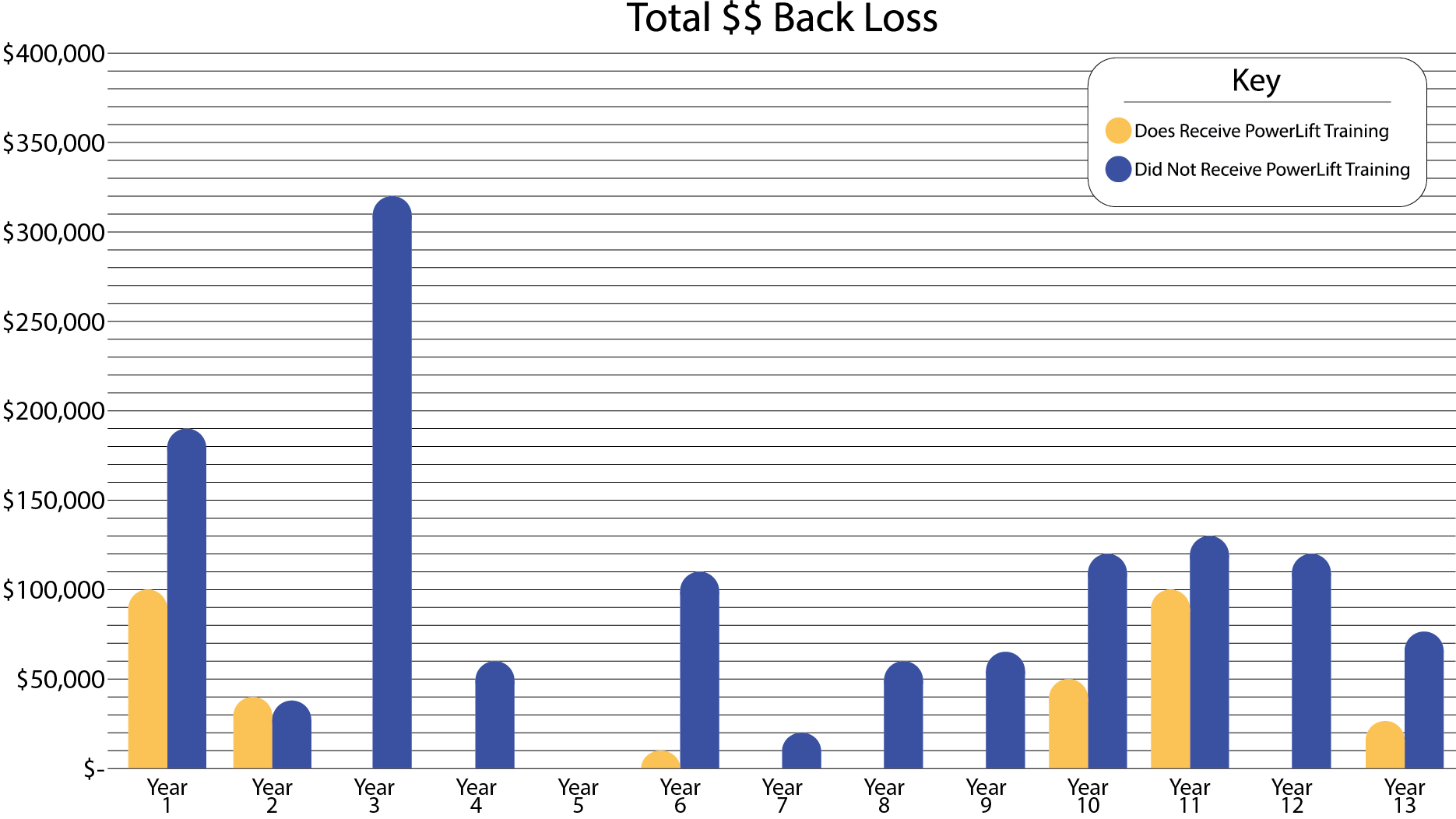

This is the story of two nearly identical companies, one that adopted PowerLift and one that did not. Unfortunately, the company that opted for the traditional squat lift training, lost a staggering $1,308,000 due to work-related strain and sprain injuries. The company that received the PowerLift training lost only $325,000 over a 13 year period, a savings of nearly $1,000,000. In fact, two years after the initial training the company that opted for PowerLift saw $0 in back loss due to injuries for three years in a row.

These kinds of results are hard to argue with and they show that PowerLift can save your business a lot of money and save your employees a lot of pain and injury. The thing that sets PowerLift apart from the rest is simply that IT WORKS.

The truth of the matter is that a lot of these injuries could have been avoided if these employees had received proper training for material handling.

The companies being compared are similar in number of employees and are owned by the same parent company. Both are road construction companies which build roads, bridges, and overpasses. The two companies also both maintain separate mining operations to supply their need for aggregate. The decision was made by the parent company to allow local management latitude in choosing what they thought was the best suppliers, including job site safety training programs. The data regarding injuries were followed closely over the course of 13 years and are very revealing.

The employees of these companies work long hard days during the construction season and engage in heavy labor tasks for at least 8-10 hours a day, 8 months out of the year. PowerLift training was well received by the employees especially when they realized it demonstrated a practical and safe way to complete their tasks.

The smaller classes allowed more room for hands-on training with the various props that were brought to the classroom. The props included objects like ground pounders, shovels, sandbags, barrels, pipes and anything else that could be safely brought into the classroom. Subsequently, our trainer went to the work site to observe and document the actual tasks performed by the employees and created PowerLift Safety Talks showing how to safely perform those tasks using the PowerLift technique. The Safety Talks are then used as continued demonstration training by the supervisors for the employees in the field on a regular basis. The result is a decrease in injuries that has been seen every year since.

PowerLift® Can Save Your Company Money and Your People Pain

Tried and proven material handling training for your entire employee population. Our unique training styles are built to seamlessly integrate into your company’s safety culture or help build you a new one. PowerLift training is so vertical that it will fit into virtually all work environments.

Training that Goes Beyond The Classroom into the Job Site

PowerLift training isn’t the one-time classroom training that we’ve all sat through and have never used. After a classroom and on-site training, we give your company access to the full PowerLift Library for continued training at your facilities. These include over 1,200 Safety Talks for safety briefings, training materials, Safety Talk videos, and much more.

PowerLift is a completely new way to push, pull, bend, reach, sit, stand, and lift. PowerLift is used in every kind of industry you can imagine, from Nursing Homes to Nuclear Plants. The reason PowerLift is so successful is that it actually works in everyday work situations and is not the typical lifting training you may have had to sit through before.

Testimonials

180 people went through the program … not one negative response. I couldn’t believe all the people coming up to me with positive things to say

The most impressive number associated with injuries has come from an $80,000 refund from our worker’s comp group in the form of a really easy to receive check.

Effective? Yes, because it is very practical. I am amazed people use it and I have actually seen people intervening with others to remember to use the PowerLift.

People can’t believe the difference it makes using the PowerLift® [lifting] technique versus what they were using before. It just feels a lot easier

Some of Our Clients

PowerLift® Intro to Material Handling Safety Training

PowerLift is a 3-Phase Training Program

Classroom Training

Your trainers will gain all of the knowledge and materials necessary to teach PowerLift to your employee population. Training can be administered online or with an in-person training session.

Job Site Training

After each class, the participants need to be shown how to apply the techniques to their job tasks. Learning in the classroom is one thing but training in the real world environment will ensure retention fo the material.

Ongoing Training

Keep the information flowing by using the over 1,200 PowerLift Safety Talks at safety briefings, the Online Overview course for refresher or new employee training, Safety Talk videos, and much more. PowerLift isn’t a one and done training program, ongoing training and implementation are necessary for creating an effective safety environment.

Purchase our:

- In-person training session

- Online training

- Training materials

- and much more…