Safety Training Programs Actually have a Lifecycle

For many companies, a safety training program’s lifespan goes something like this:

- At the corporate level, concerns about the detrimental effect of poor lifting habits (especially on the bottom line) cause management to choose the safety program du jour.

- This gets handed down through the ranks to Operations, who implement the chosen program through Safety Management.

- HR or PR (or equivalent) hypes up the program rollout and generate a lot of hype and excitement.

- The atmosphere buzzes with chatter about the new safety initiative. Evidence is provided by illustrated safety posters featuring large, friendly fonts. These appear magically around the workspace practically overnight.

- Simultaneously, employees participate in the program.

Now, fast-forward a few weeks.

- The safety program is no longer new and shiny. The rollout is just an event on the company’s timeline.

- Corporate checks the safety program off their list of priorities.

- Posters lose their shine. They are now part of the background clutter.

- The once-new safety training program is now lost in the drift of old lifting habits.

- Safe material handling returns to the status quo.

- Statistics may show a temporary decrease in injuries, but the decrease is just another blip in a line of blips that follow every safety training. And will likely follow the next one. And the next one.

Let’s be really blunt: most safety training programs do not work over time.

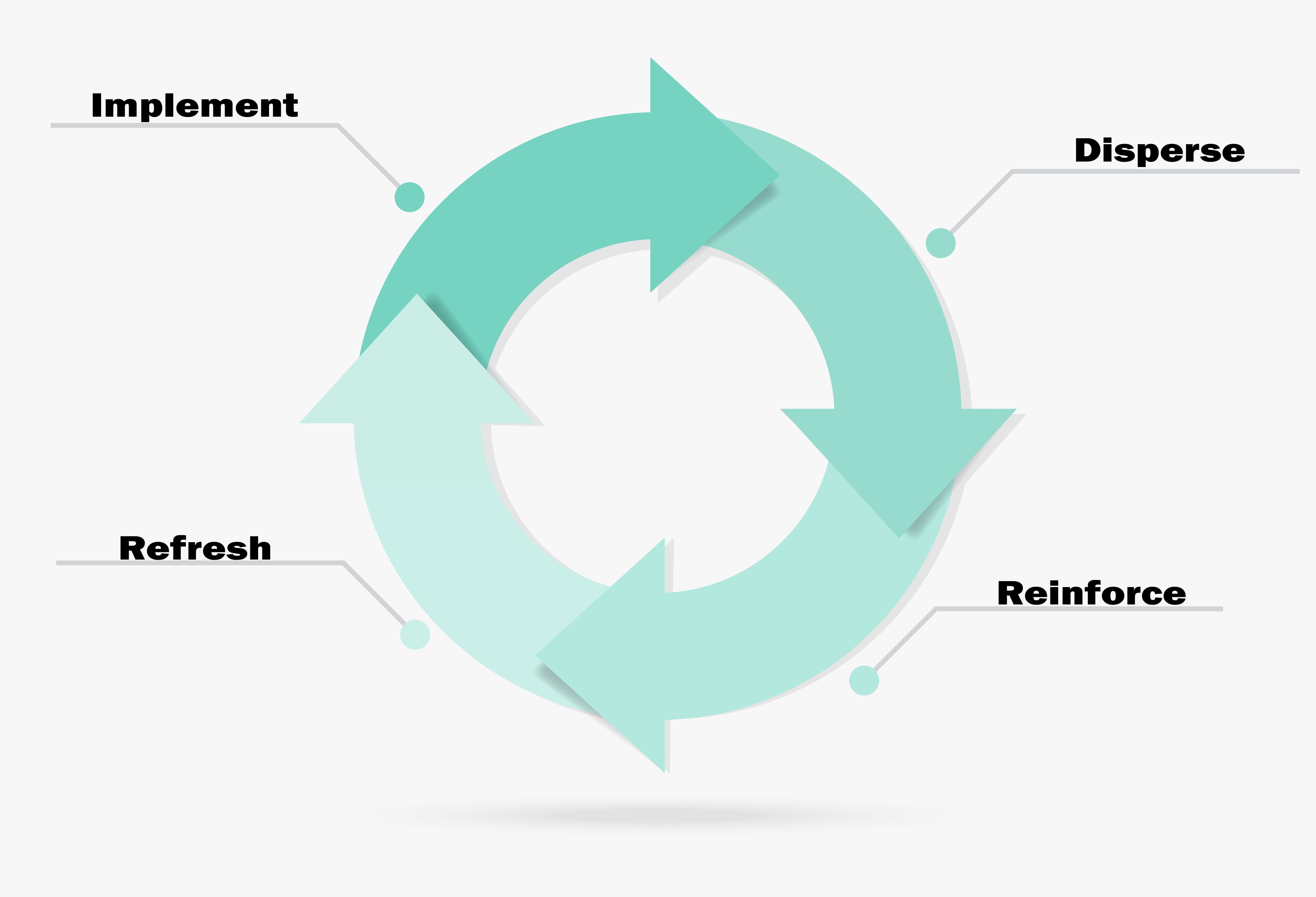

The only way for safety training to be truly effective is to make sure that it sticks: it must be sustainable.

According to the Bureau of Labor Statistics:

- Over 1 million workers suffer from back injuries on the job every year.

- 3 out of 4 back injuries in the workplace are caused by improper lifting techniques..

- 1 out of every 5 workplace injuries or illnesses are attributed to back injuries.

And it ain’t cheap, either:

- The annual cost of back injuries to employers is counted in billions of dollars.

- 25% of all compensation claims are for back injuries.

- Thus far, we haven’t even begun to count the cost of the pain and suffering that employees experience. Nor have we considered the wider impact that an injury can have on the relationships, family, and friends of the injured person.

While the above statistics focus on back injuries, other parts of the musculoskeletal system are not exempt. 34% of all lost-workday injuries and illnesses are related to musculoskeletal disorders, many of which are caused by improper lifting. These incidents occur despite the implementation of safety- and lifting programs.

Insanity = Doing the same thing, expecting a different result.

Anyone who has had to learn how to lift heavy materials at work has been taught the following:

- Keep your back straight.

- Place your feet shoulder width apart.

- Squat down.

- Lift with your legs, not your back.

- Keep the weight near your torso.

Known in some circles as “body mechanics,” this is considered the standard way to handle materials and loads. Yet, despite the ‘correctness’ of this method, we still injure our backs. Why?

Consider the power of habit.

Most of us learned to lift incorrectly from the time we were young. It became a habit, practiced over years, even decades. A training program must overcome those habits; once the training program is over, we do what is familiar – and therefore easier – to us. Most programs don’t equip us to deal with our own habitual lifting behaviors once the program is over. Quite the contrary: we’re taught the technique, and left to our own devices for better or ill.

To develop a new habit takes time. Even better, create a community around safe lifting habits.

A safe material handling success story begins with a commitment to train your employees over time.

PowerLift® Training begins with lifting methods that work, and work naturally. PowerLift® takes into account the human body’s actual, physical mechanics, and works with the natural, physical structure of the body to lift, reach, bend, stretch, push and pull. One of the core concepts is to lower the center of gravity, achieved by lifting with a wide stance. This increases stability, freeing up muscular power for lifting (as opposed to balancing).

Ongoing effectiveness comes with ongoing training. PowerLift®’s Train-the-Trainer concept Incorporates positive feedback, incentives, peer-coaching and peer-training as part of the daily routine. Correcting old, less effective lifting habits then becomes an opportunity to share new techniques that work consistently. Those new techniques quickly become new habits. And, distinct from a priority, PowerLift® Training take safe material handling from a new method to a new habit to a safety value.

Like you, we’re committed to the safety and health of your workers.

And we’re here to support you in your commitment to keeping your workforce safe, healthy, and productive. Let us know how we can help.

Recent Comments