It’s easy to agree that strain and sprain injuries are a major issue for people in the material handling business, especially when you hear that a single back injury can cost a company on average $40,000-$80,000 per employee hurt. Injuries like these are often long-lasting and very frustrating for businesses and the employee who endures them. It’s so frustrating because most if not all of these injuries could have been prevented if programs for proper lifting technique had been implemented into the company’s safety culture. Luckily for people who work in material handling industries, there is a new safe lifting program out there that really works.

Just about everyone in almost every industry has had to go through some kind of lifting training in their professional career. What they teach you in these training sessions is the typical shoulder width stance and go down and do a deep knee bend. The information leaves everyone as they leave the training room because they know after trying it once or twice that it doesn’t work. It doesn’t work because this stance forces you to be on the balls of your feet, it puts you in a deep knee bend which is nearly impossible to get out for an aging workforce, and your knees are in the way forcing you to swing the load out in front of your knees. People know these techniques make no sense so they don’t use them and revert to their old way of doing things. Yet, we’re still stuck with the issue what is the proper lifting technique?

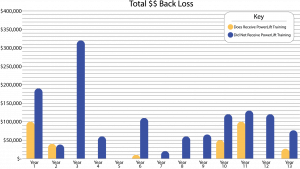

PowerLift is a totally new way to push, pull, bend, reach, sit, stand, and of course lift. We teach a twice shoulder width stance with several patented techniques designed to work in all situations a material handler encounters. One of the biggest reasons we stand out in the material handling safety training industry is that what we teach actually gets used by employees. People use it because it works and has been proven to work by reducing strain and sprain injuries time and time again from industry to industry. This can be best seen in one of our PowerLift Case studies. This particular case study compares two nearly identical construction companies, one that applied the PowerLift proper lifting technique and the other did not. Over a period of 13 years the company that chose to implement PowerLift into their safety culture saved over $1,000,000,000 compared to the company that did not.

The PowerLift system is designed to integrate flawlessly into any companies safety culture or help be the foundation of a new one. Contact us to try a free demo today and be one step closer to become a PowerLift facility.

Recent Comments