What prevents many workplace injuries and keeps your pants from falling down, all at the same time?

Give up? It’s a belt.

And it’s a belt unlike any other.

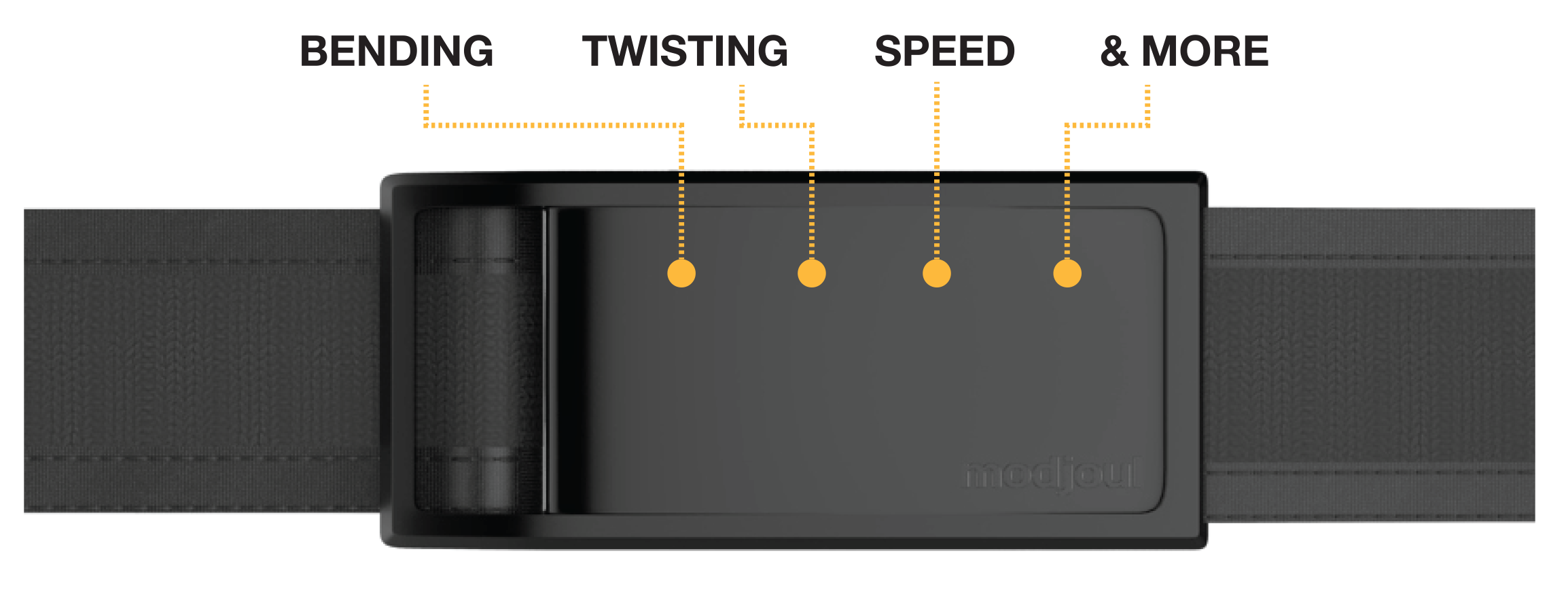

The SmartBelt by Modjoul uses embedded hard- and software to monitor how people move, where they are, and the conditions of the environment in which wearers find themselves. The collected data is used to identify the movement, activities, and actions of each wearer, assessing actions that can lead to musculoskeletal and neural injuries. The SmartBelt even provides real-time feedback when it detects movements that put the user in immediate or imminent risk for injury. Over time, the SmartBelt provides information on behavioral patterns that require correction and even physical locations where risky movements are most likely, making the workplace safer for all workers. And when you couple the SmartBelt with material handling training like PowerLift® Training the results can mean a safety culture that reduces workplace injuries dramatically.

The winning combination of PowerLift and the SmartBelt gives us many reasons why workplace injuries no longer have to be the norm. Here are 5 of those reasons:

1. The technology and techniques exist today:

It wasn’t that long ago that wearable technology was strictly limited to the telling of time. Any other uses for wearable technology were the domain of entertainment, like Star Trek or The Jetsons. The SmartBelt, on the contrary, is boldly going where no electronic safety equipment has gone before. At the same time, the safe material-handling techniques provided by PowerLift become hardwired habits through training and real-time practice. The techniques are supported by trainers and coaches who are also peers and co-workers. Together, the SmartBelt and PowerLift create a condition of optimum safety for each and every employee.

2. Wearable technology – and injury prevention – is now a simple matter of getting dressed.

The SmartBelt has history on its side. Human beings have worn belts since the Bronze Age. That’s over 5,000 years of belt-wearing. So why not wear a belt that protects us from making mistakes that can lead to (sometimes severe) injuries? The SmartBelt fits through standard belt loops, and comes in several different lengths to fit a wide variety of body-types. Each belt is equipped with eight sensors that, together with GPS, faithfully provide 125 data points on a user’s motion and location every second. Data is fed, via wifi, to the cloud where it is analyzed and stored. The belt itself is capable of storing data for 2 weeks if the wifi connection is disrupted. Haptic feedback serves as a warning to the user if a movement or action is potentially risky, according to baselines that are custom-set at the worksite. The SmartBelt also employs machine learning, and adapts to the user over time. This is no futuristic fad. This is functional fashion at its finest.

3. SmartBelt + PowerLift is relatively inexpensive to introduce and implement.

OSHA estimates that workplace injuries cost employers in the US almost $1 billion per week. In 2017, costs exceeded $161 billion in workers compensation costs alone. All those zeroes are bottom line numbers only. They do not include the far greater cost to the workers, their families and society in general. Now we’re not saying, “strap on the SmartBelt and all that will go away.” But we can’t argue with the numbers:

- 30% – 40% reduction of risky activity;

- Employers break even at less than 8% reduction of injuries; and

- 80% reduction of risky behaviors when coupled with coaching, and changes in material handling processes.

“…when coupled with coaching, and changes in material handling processes” is where technology and technique intersect. See, wearing the SmartBelt will do a lot to reduce workplace injury. But when you integrate safe material handling techniques like PowerLift in tandem with wearable technology, you establish a culture of safety in the workforce, further reducing the chances that an injury-incident will happen.

4. It’s easy to implement.

Introduction and adoption of new programs can be a nightmare. This isn’t one of those programs. Because it isn’t a program. The SmartBelt works seamlessly with safety training and coaching systems like PowerLift. Technology meets technique in a way that empowers a safe workforce, transforming the way your employees relate to safety, and to each other. PowerLift creates a culture of safety. The SmartBelt empowers and supports that culture. Technique and technology work together to create a win-win unprecedented in most workplaces.

5. Meaningful data and information are easily accessible.

Do you have a mobile device? Do you know many people who don’t? Since the SmartBelt is connected to the cloud, the metrics, performance, and activities of the individual user and standards are as easy as opening an app. The SmartBelt collects and summarizes data. Using the summaries and collected information, supervisory and management staff can identify problem locations in the workspace (where there may be higher frequencies of incidents) and make necessary adjustments. Workers who require additional support can be identified and trained to reduce their risks of injury. Simultaneously, PowerLift-trained employees provide on-the-job coaching and guidance on correct postures, reducing on-the-job injury risks. Again, we have a seamless merging of technology and technique.

It may be the ultimate injury prevention system. But the SmartBelt and PowerLift are only 2 components. There is a third component: the human beings that make up any human system. It’s something of a paradigm shift. Machine Learning still looks like the new kid on the block. Both PowerLift and the SmartBelt are tools which could make the difference in the world of workplace safety. It’s up to us to use them.

Look, everyone wants a safe workplace. So when the technology of Modjoul’s SmartBelt meets PowerLift’s safe material-handling techniques, you get optimum protection from workplace injuries. Together, PowerLift and SmartBelt could literally keep us – and possibly our pants – from falling down on the job.

Recent Comments